Safety in electrical and electronic circuits is vital for new learners and vetted experts alike. This lessons goes through some of the basics that you need before you start your journey in electronics DIY and Arduino.

List of Content

1. Why Safety Matters

Working with electronics involves several risks that can cause:

- Personal injury (burns, shocks)

- Equipment damage

- Project failures

Following proper safety practices ensures successful and accident-free projects.

2. Common Hazards & Prevention

Electrical Shocks

An electrical shock is a result of current (electron flow) passing through the body, which may lead to severe injury, burning, paralysis or death (may Allah protect us all).

Examples of how it happens:

- Coming in contact with live circuits while power is on. This can happen directly (accidentaly touching) our inderctly, like touching a metal part in contact with an exposed wire.

- Working with wet hands or tools

- Using damaged insulation

Prevention:

- Always disconnect power before making changes

- Use insulated tools (tools with plastic handles, wooden handles, etc)

- Keep you work area dry, and avoid bringing foods and drinks nearby (spilling almost never happens intentionally, but it still happens).

Short Circuits

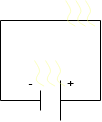

One of the most common reasons for huge accidents, casualties, electrical fires and explosions is when the positive (+) pole directly touches the negative (-) pole with nothing in between, which is VERY VERY VERY VERY VERY VERY VERY BAD. Look at the diagram below.

How can it happen:

- Bare wires or conductors touching

- Incorrect connections

- Component leads touching

Prevention:

- Cover exposed conductors

- Double-check connections

- Use current-limiting resistors

Overvoltage

Electronic parts generally have a voltage rating, which indicates the maximum (and minimum) voltage they can operate at. Giving excess voltage to electronic components and parts lead to generation of excess current through the component, leading to the part failure, since high current and voltage means high power (P= IV), which means high dissipated power (heat) and the burning of the part (and a smoke smell!!).

How can it happen:

- Wrong connections

- Not reviewing components Max ratings

- Using wrong power adapter

- Incorrect voltage regulators

- Miswiring power rails

Prevention:

- Verify component voltage ratings

- Use multimeter to check supplies

- Implement voltage regulators when needed

Electrostatic Discharge (ESD)

Electrostatic charge is generated all around us, usually when surfaces of two different materials come into contact or friction. After the charge builds up, it can get released on contacting another object. If this happens to an electronic chip, like an Integrated Circuit (IC), it leads to sudden flow of a static electricity, usually very large but very short, which may damage the IC.

How it happens:

- Walking on carpet (generated several thousands of Volts) or handling plastic bags

- Handling components without grounding

- Dry environments

Prevention:

- Use anti-static conductive mats

- Wear grounding wrist straps

- Store ICs in conductive foam or ESD safe bags

Overheating

Even if you haven’t overloaded the component with voltage, it can still fail (burn) due to overheating after some time. This is why you need to help the component breath the heat out. Some components that dissipate a lot of heat can also damage a nearby component if it is close enough (most likely on PCBs).

How it happens:

- Not using heat sinks or heat paste

- Poor ventilation of the entire system

- Prolonged soldering (damage before usage)

Prevention:

- Provide adequate cooling methods

- For resistors, use proper wattage

3. Workplace Organization Tips

A well-organized workspace helps preventing accidents and saves A LOT of time.

Part Management and Storage

- Sort electronic components by type/size and according to usage frequency

- Label containers clearly

- While labeling, label each drawer with a letter range rather than a few part names

- ex: LT-LZ (includes everything from LT11111 to LZ9999)

Tools Storage

- Keep most frequently used tools near and accessible

- Label each drawer as much as possible

- Store sharp tools properly

Final Safety Reminder

“Test Before Touch” Protocol:

- Visual inspection

- Multimeter check

- Power-on test (brief)

Accident still can happen, yet having taken precautions and making a proper emergency plans, including following emergency instruction of your lab/workplace, helps reducing casualties. We wish you safe learning, testing and experimenting. After learning the basics of safety, you can start exploring electronics with Samerli!

Leave a Reply